| Common Temperature | 1100℃ |

| Model | AJ-STCL |

| Power Supply (AC) | 380V |

| Thermocouple Model | Type K thermocouple |

| Installation Position of Heating Elements | Around and at the bottom of the furnace chamber |

| Temperature Control Precision | ±1℃ (integrated circuit control, no overshoot) |

| Hot Air Stirring | To make the temperature in the high-temperature furnace chamber more uniform, the electric furnace is designed with 4 high-temperature stirring fans installed on the top, distributed in the front, middle and rear; |

| Common temperature: 950-1050℃, fan material 310S, water-cooled, variable frequency speed adjustable. |

| Furnace Temperature Uniformity | ±5℃ (no-load) |

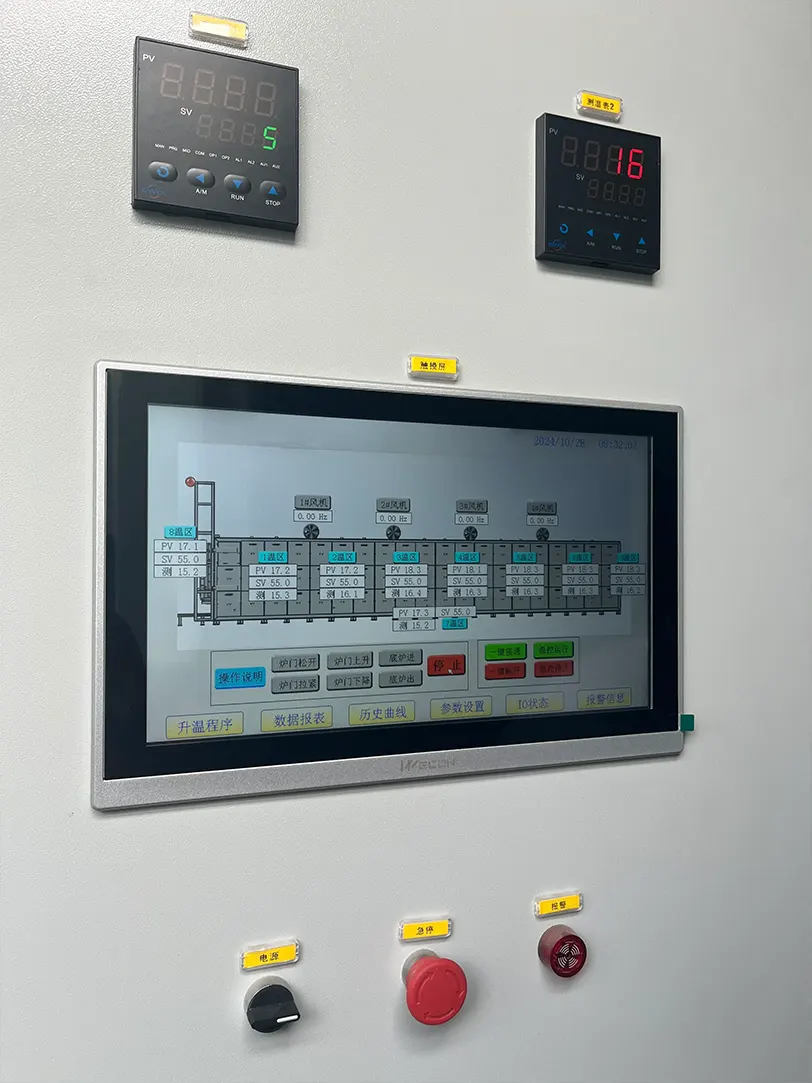

| Multi-point Independent Control | 9 sets of independent temperature control units, located in 6 sets on both sides, 1 set at the bottom, 1 set at the furnace door, and 1 set at the rear wall. |

| Heating Rate | Freely adjustable, with a range of 20℃/min (fastest) to 1℃/h (slowest) |

| Heating Elements | High-temperature alloy resistance strips containing molybdenum (surface temperature up to 1380℃) |

| Furnace Body | Processed by CNC machine tools, with processes including polishing, grinding, pickling, phosphating, plastic powder spraying, and high-temperature baking. It features a two-color design, novel and attractive appearance, and advantages such as oxidation resistance, acid and alkali resistance, corrosion resistance, high-temperature resistance, and easy cleaning. |

| Furnace Body Structure | Single-layer shell structure |

| Furnace Door Opening Method | The furnace door and furnace chamber are integrally designed, and the furnace door is opened electrically upward (with controllable opening height) and equipped with a locking device; |

| The loading platform is opened electrically, driven by a motor-driven reducer to move in and out, and is equipped with limit switches. |

| Cooperation Between Furnace Mouth and Loading Platform Refractories | The furnace mouth and loading platform refractories adopt a stepped cross-sealing design, with angles on both upper and lower parts of the refractories. The opening angle of the loading platform increases, and gradually decreases as the platform closes. |

| Loading Platform Capacity | Customer-defined 10 tons |

| Loading Platform Movement | Variable frequency electric reducer |

| Refractory Materials | Alumina fiber folding blocks, featuring high operating temperature, low heat storage, resistance to rapid heating/cooling, no cracking, no slag dropping, and good thermal insulation performance. |

| Insulation Materials | High-purity alumina fiber products with an aluminum content of over 52%. |

| Furnace Body Surface Temperature | ≤45℃ during long-term continuous operation |

| Protection | Adopts an integrated module control unit with accurate control precision, designed with dual-loop control and dual-loop protection, featuring overshoot, undershoot, thermocouple break, phase loss, overvoltage, overcurrent, overtemperature, current feedback, and soft start protection. |

| Control | Uses closed-loop thyristor module trigger control (phase-shift trigger mode). Output voltage, current, or power is continuously adjustable with constant voltage, current, or power characteristics. |

| The current loop is the inner loop and the voltage loop is the outer loop. When the load is suddenly applied or exceeds the current limit, the output current of the voltage regulator is limited within the rated range to ensure normal operation of the output and regulator. |

| The voltage loop also participates in regulation to maintain stable output current and voltage within the rated range, thus protecting heating elements from excessive current/voltage impact and ensuring safe, reliable control and precision. (See electric furnace video for details) |

| Multi-point Temperature Control | Temperature control at front, middle, rear + bottom |

| Display Parameters | Temperature, temperature segment number, segment time, remaining time, output power percentage, voltage, current, etc. |

| Temperature Curve Setting | Uses an intelligent temperature controller with multiple regulation modes (standard PID, artificial intelligence adjustment APID, MPT, etc.), featuring self-tuning and self-learning functions, no overshoot/undershoot, and 30-segment program control. |

| It supports arbitrary slope heating/cooling control, with programmable commands (jump/cycle, run, pause, stop) and allows in-operation program modification. |

| Adopts an AI adjustment algorithm with curve fitting function for smooth curve control. |

| Multiple Curve Input | Customizable 50-segment program control function |